Understanding High Temp Thermocouple: Key Features and Uses

What is a high temp thermocouple? High temperature thermocouples are vital tools in industries where accurate temperature measurements are essential, particularly in extreme temperature environments. Knowing their design, features, and applications can guide you in selecting the right one for your needs. This guide covers the basics of high temp thermocouples, their key features, common applications, and tips for selection and maintenance.

What is a high temp thermocouple? High temperature thermocouples are vital tools in industries where accurate temperature measurements are essential, particularly in extreme temperature environments. Knowing their design, features, and applications can guide you in selecting the right one for your needs. This guide covers the basics of high temp thermocouples, their key features, common applications, and tips for selection and maintenance.

What is a High Temp Thermocouple?

A high temp thermocouple is a type of temperature sensor designed for extreme temperature environments, often exceeding 1000 degrees Celsius (1832 degrees Fahrenheit). These sensors operate on the thermoelectric effect, generating a voltage when two different metals connect and experience a temperature difference.

Basics of Thermocouples

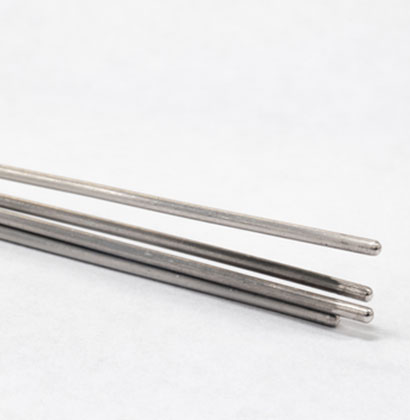

Thermocouples are made of two wires from different metals or metal alloys joined at one end, forming a junction. When the junction changes temperature, it produces a voltage that can be measured and converted into a temperature reading.

Types of Thermocouples: Several types exist, denoted by letters (e.g., Type K, Type S, Type R). Each type has different metal combinations that affect its temperature range, sensitivity, and suitability for various uses.

High-Temperature Variants: High temp thermocouples are specifically built to endure extreme conditions, making them suitable for industries like aerospace, metallurgy, and ceramics.

Advantages of High Temp Thermocouples

Wide Temperature Range: They can measure temperatures from cryogenic levels up to several thousand degrees Fahrenheit, depending on their design.

Rapid Response Time: Their simple construction allows for quick responses to temperature changes, providing real-time data.

Durability: Many high temp thermocouples resist oxidation and degradation in harsh environments.

In summary, high temperature thermocouples are critical instruments that deliver reliable temperature readings in extreme conditions, making them essential across various industries.

Explore the Fundamentals and Design Principles of High Temp Thermocouples

To appreciate high temp thermocouples, understand their design principles and operation in extreme conditions.

Construction and Materials

High temperature thermocouples are made from materials that withstand high thermal stresses. Common materials include:

- Noble Metals: Platinum and rhodium are used in Type S and Type R thermocouples due to their stability and oxidation resistance.

- Metal Alloys: Nickel-chromium (Type K) and nickel-aluminum (Type N) handle high temperatures while providing good accuracy.

Working Principle

High temp thermocouples operate based on two key phenomena:

- Seebeck Effect: Joining two dissimilar metals at one junction and heating them generates a voltage proportional to the temperature difference between the hot junction and the cold junction.

For example, during testing in an aerospace application, engineers rely on the Seebeck effect for precise temperature readings in jet engines.

- Cold Junction Compensation: Knowing and compensating for the temperature at the reference junction is crucial for accuracy, especially in high-temperature applications with varying ambient conditions.

Calibration and Accuracy

High temperature thermocouples require careful calibration for accurate readings. Calibration involves comparing the thermocouple’s output against a known standard, typically in controlled temperature settings.

Standard Calibration Methods: These methods include using ice point references or fixed point cells for higher accuracy.

Factors Affecting Accuracy: Environmental conditions, installation errors, and thermocouple aging can impact performance, making regular calibration essential.

Key Features of High Temp Thermocouples

Understanding key features helps ensure that a high temperature thermocouple meets your application’s needs.

Temperature Range

High temp thermocouples operate over a wide temperature range. Here are some key points:

Type K Thermocouples: Typically measure from -200 °C to 1260 °C (-328 °F to 2300 °F), making them versatile for various applications.

Type S Thermocouples: Suitable for higher temperatures, measuring up to 1600 °C (2912 °F), often used in laboratories and industrial furnaces.

Response Time

The response time of a high temp thermocouple is critical in processes with rapid temperature changes.

Thin-Walled Designs: Many high temperature thermocouples feature thin-walled constructions that enhance their response to temperature changes.

Installation Location: Proper installation ensures that the thermocouple is directly exposed to the temperature being measured, minimizing lag.

Durability and Resistance

Durability is essential for high temp thermocouples in harsh environments:

Oxidation Resistance: High-quality thermocouples are often coated or made from oxidation-resistant materials.

Mechanical Strength: The physical integrity of the thermocouple is crucial in settings exposed to vibrations or mechanical stress.

Accuracy and Stability

Accuracy and stability are vital for precise temperature measurements.

Calibration Standards: Regular calibration against recognized standards helps thermocouples maintain accuracy.

Quality Control: Buying thermocouples from reputable manufacturers with strict quality measures significantly impacts performance and reliability.

Common Applications of High Temp Thermocouples

High temp thermocouples are used in various industries due to their ability to operate in extreme conditions.

Aerospace Industry

In aerospace, high temp thermocouples are used for engine testing and monitoring. Their capacity to withstand high temperatures makes them ideal for measuring exhaust temperatures in jet engines.

Engine Testing: Accurate readings are crucial during performance testing to ensure safety and efficiency.

Thermal Protection Systems: They monitor surface temperatures in spacecraft during re-entry.

Metallurgy

The metallurgy industry relies on high temp thermocouples for processes like metal casting and heat treating.

Heat Treatment: Accurate temperature measurement ensures proper treatment of metals, affecting their strength and durability.

Casting Processes: Thermocouples monitor temperatures in molds and furnaces to ensure quality and consistency in metal properties.

Ceramics and Glass Manufacturing

High temperature thermocouples are essential in ceramics and glass manufacturing, where processes involve extreme heat.

Kiln Monitoring: They monitor kiln temperatures to ensure uniform heating for optimal material properties.

Process Control: Accurate readings allow for better control of the manufacturing process, reducing waste and improving quality.

Automotive Industry

In the automotive sector, high temp thermocouples are used in engine testing and exhaust monitoring.

Engine Performance Testing: Ensuring engines operate within safe temperature ranges during testing is vital for performance and safety.

Emission Control Systems: Monitoring temperatures in exhaust systems helps maintain performance and compliance with regulations.

Choosing the Right High Temp Thermocouple

Selecting the right high temp thermocouple involves understanding your specific application and environmental conditions.

Factors to Consider

Temperature Range: Determine the maximum and minimum temperatures your application will encounter and select a thermocouple type that can handle these extremes.

Material Compatibility: Consider the materials involved in your process. Certain thermocouples may not suit corrosive environments.

Response Time Requirements: Assess how quickly you need the thermocouple to respond to temperature changes.

Environmental Conditions: Factors such as humidity, pressure, and potential exposure to contaminants should influence your choice.

Types of High Temperature Thermocouples

Type K: Best for general-purpose applications, capable of measuring a wide range of temperatures.

Type S: Ideal for high accuracy in laboratory settings and extreme temperature applications.

Type R and Type B: Suitable for very high temperatures, often used in industrial furnaces and laboratories.

Consult with Experts

When in doubt, consult industry experts or manufacturers to ensure you choose the right high temp thermocouple for your application. They can offer insights based on experience and knowledge of the latest technologies.

Maintenance and Calibration Tips for Longevity

Proper maintenance and calibration are essential for maximizing the lifespan and accuracy of high temperature thermocouples.

Regular Inspection

Conduct routine inspections of thermocouple installations to identify signs of wear, damage, or degradation.

Physical Checks: Look for cracks or corrosion that may affect performance.

Electrical Testing: Periodically test the electrical connections to ensure they are secure.

Calibration Practices

Regular calibration is vital for maintaining accuracy.

Choose Calibration Intervals: Determine a calibration schedule based on your application. Critical uses may require more frequent calibration.

Use Reference Standards: Ensure the calibration process uses recognized temperature standards for accuracy.

Installation Considerations

Proper installation significantly affects the performance and longevity of high temp thermocouples.

Avoid Mechanical Stress: Ensure thermocouples are installed to minimize mechanical stress and potential damage.

Correct Positioning: Position thermocouples to measure the process temperature accurately.

Cleaning and Maintenance

Regular cleaning helps maintain performance.

Remove Contaminants: Clean the thermocouple and surrounding area to prevent contaminants from affecting readings.

Follow Manufacturer Guidelines: Adhere to the manufacturer’s recommendations for cleaning and maintenance to avoid damage.

Safety Considerations

When using high temp thermocouples, especially in hazardous industries, it is crucial to observe safety precautions:

Protective Equipment: Always wear appropriate personal protective equipment (PPE) when working in extreme temperature environments.

Safe Handling: Ensure that thermocouples are installed and maintained without risking exposure to dangerous temperatures or materials.